Product description

KX900 series powder concentrator sand cement powder concentrator three separation powder concentrator

1. Description

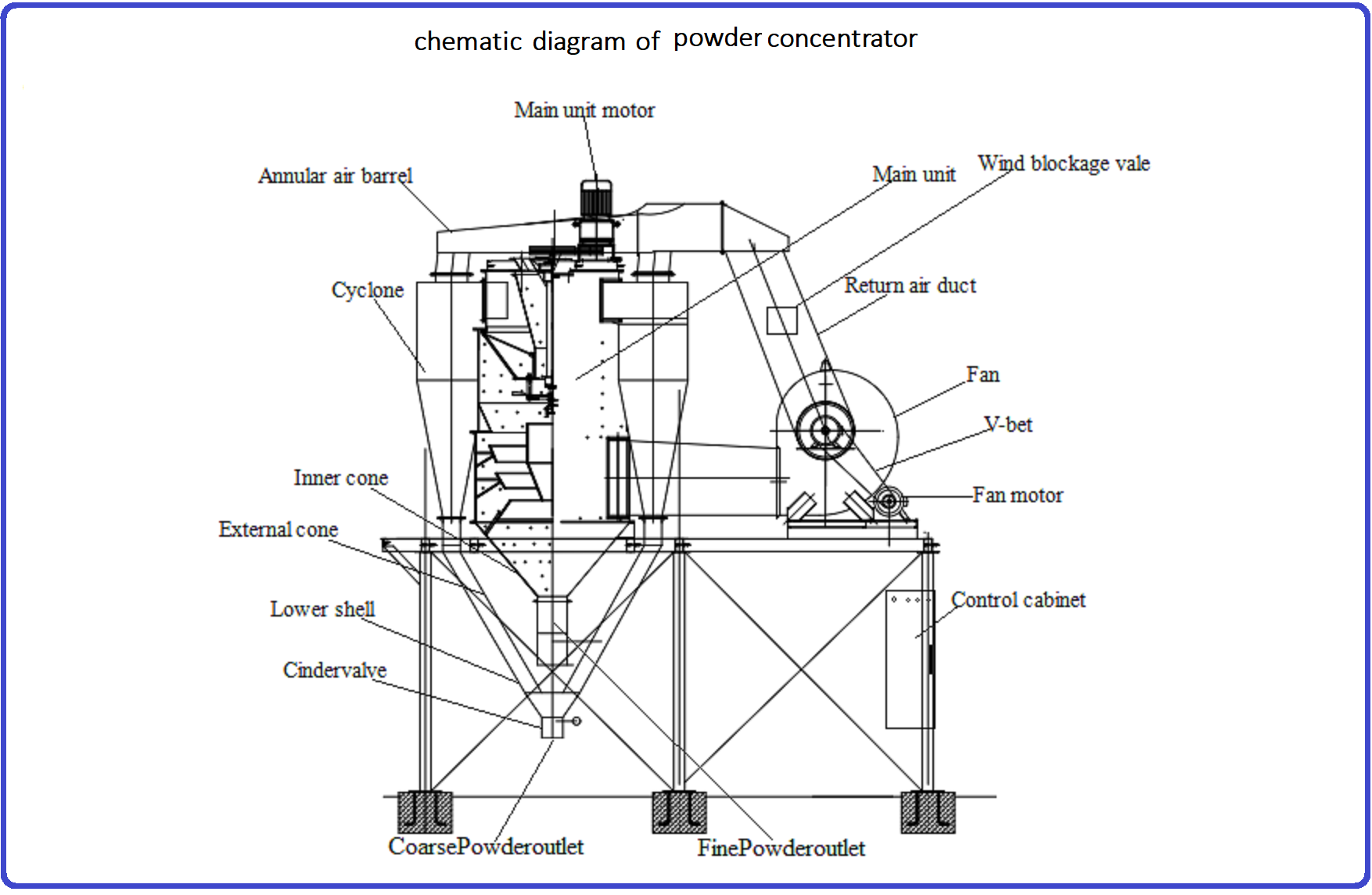

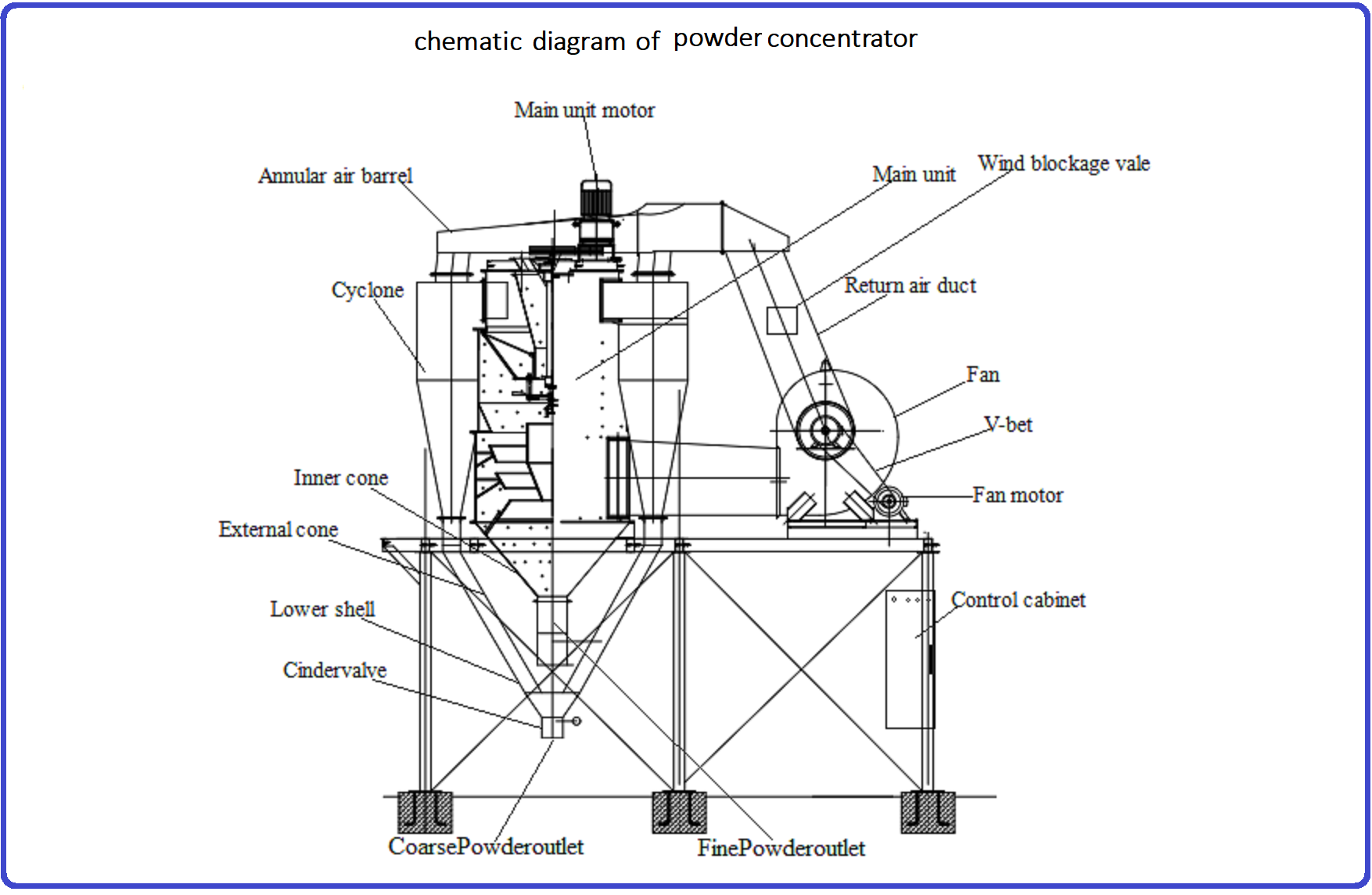

There are many types of powder concentrators, and different types are suitable for different materials. Different models are also made according to customers' requirements for material fineness. The common separator are cyclone separator, three separation separator, centrifugal separator, special separator for coal mill, special separator for calcium powder, etc. Later, many high-efficiency powder concentrators and high-efficiency three separation powder concentrators were developed. They are the new generation varieties that improve the deficiency and increase the output on the original basis.

Cyclone separatorThe cyclone separator drives 60 blades on the rotary table to rotate through the speed regulating motor and two-stage deceleration to form a cyclone separatorHorizontal cyclone separatorHorizontal cyclone separatorClassification of powder. The speed of blade speed is adjusted according to the size of finished powder. In order to obtain fine-grained powder, the rotating speed of the blade must be increased to increase the contact between the blade and the powder, so that the unqualified powder is thrown to the outer wall by the blade and separated from the air flow. The coarse powder falls into the grinding chamber for re grinding due to the action of self gravity. The qualified finished powder is sucked into the large cyclone collector by the blade with the air flow. After the air flow and the

2. Technical parameter

| Model | Capacity (t/h) | Spindle motor | Supporting fan |

| Model | Power/Kw | Speed ranger/m | Model | Power/Kw |

| KX50 | 5-7 | TCT110-4A | 4 | 125-1250 | KXF-N08C | 15 |

| KX500 | 21-28 | TCTL255-4A | 11 | 125-1250 | KXJF-N08C | 30 |

| KX600 | 30-35 | TCTL255-4B | 15 | 125-1250 | KXJF-N010C | 37 |

| KX700 | 35-46 | TCTL255-4C | 18.5 | 125-1320 | KXJF-N012.5C | 55 |

| KX800 | 55-65 | TCTL280-4B | 30 | 125-1320 | KXJF-N014C | 90 |

| KX900 | 70-86 | TCTL355-4A | 55 | 125-1320 | KXJF-N16B | 110 |

| KX1000 | 90-115 | TCTL355-4B | 75 | 125-1320 | KXJF-N16B | 132 |

| KX1200 | 120-160 | T380M-4 | 90 | 125-1480 | KXJF-N020B | 160 |

3. Folding three separation powder separator

Three separation separatorThree separation separatorThe three separation powder concentrator breaks through the two separation theory of "coarse and fine powder" in the conventional closed-circuit grinding system, and divides the material into three, namely coarse powder, medium coarse powder and fine powder. The product system has the advantages of simple configuration and low cost, and can greatly improve the output of the mill. With reasonable internal structure and remarkable powder selection effect, it is the first choice to improve the product quality of grinding system after the implementation of the new cement standard.

powder are separated, the powder is collected.

4. Centrifugal separator

Centrifugal powder concentrator is the first generation of wind classifier. After transformation, the centrifugal powder concentrator solves the problem of high circulating load of the previous generation of centrifugal powder concentrator, which can not only improve the output of the mill, reduce the cost, but also improve the product quality.

Centrifugal powder concentrator is the first generation powder concentrator for cement industry. It was invented by British munfound and moadie in 1885. Over the past 100 years, with the progress of technology and the improvement of production process requirements, it has experienced a series of technical transformation and developed into a variety of structural forms, such as smnevam type, C acrico type, Tso type and heyd type. The structure and classification principle of these separators are similar. The common feature is that the air flow of the separator is internal circulation, that is, the air separator, the circulating fan and the cyclone collecting fine powder are combined together, which is also called internal circulation air separator. By using NHX high efficiency rotor separator technology to transform the traditional centrifugal separator, the separation efficiency of the separator and the output of the grinding system can be improved. This technology is especially suitable for the old line transformation with insufficient funds for technical transformation, low mill height and difficulty in replacing new high-efficiency powder concentrator. It has certain popularization and application value and market application prospect.

5. Factory manufacturing and transport

tag:

Pulse dust collector industrial environmental protection dust collector mine dust removal equipment